Hafner’s ATEX Valve Series boast a wide range of valves suitable for explosion hazardous areas and applications. Available in 3/2, 5/2, and 5/3-way valve options to meet various applications in explosion hazardous areas.

Product Overview

● Hafner provides a comprehensive range of ATEX valves from manually and mechanically actuated to pneumatically or solenoid actuated valves to tailor to customer needs and requirements in the Oil & Gas (O&G) sectors, Offshore applications, Food & Beverage (F&B), Palm Oil and Chemical industries.

● Hafner ATEX valve range also includes NAMUR-interface and CNOMO-interface valves.

● Hafner products are available for explosion hazardous environments classified under product group II.

● Hafner products are certified for SC3 or Safety Integrity Level 3 (SIL 3) capable.

● Available in two different thread standards namely BSP (sizes from G1/8″ ~ G1/2″) and NPT (sizes from 1/4″ ~ 1/2″).

● Valves can be configured on demand to feature either aluminum or stainless steel 316L (1.4404) components designed to cater for different environments and temperature classes.

Category / Zones

Below is a table of the different categories and zones for explosion hazardous environment compliance. Hafner products covers environments in Zone 1, 2, 21 and 22.

| ZONES FOR GASES | ZONES FOR DUST | |

|---|---|---|

| CATEGORY 1 | Zone 0 Area in which an explosion hazardous atmosphere consisting of air and inflammable gases, vapors or fog is present constantly or over a longer period of time. > 1000 hours/year | Zone 20 Area in which an explosion hazardous atmosphere consisting of a dust-cloud or a mix of air and dust is present constantly or over a longer period of time. > 1000 hours/year |

| CATEGORY 2 | Zone 1 Area in which there is a probability that under normal conditions an explosion hazardous atmosphere consisting of air and inflammable gases, vapors or fog can be present. 10 -1000 hours/year | Zone 21 Area in which there is a probability that under normal conditions an explosion hazardous atmosphere consisting of a dust-cloud or a mix of air and dust can be present. 10 - 1000 hours/year |

| CATEGRORY 3 | Zone 2 Area in which once and a while an explosion hazardous atmosphere consisting of air and inflammable gases, steam or vapors can be present. <10 hours/year | Zone 22 Area in which once and a while an explosion hazardous atmosphere consisting of a dust-cloud or a mix of air and dust can be present. <10 hours/year |

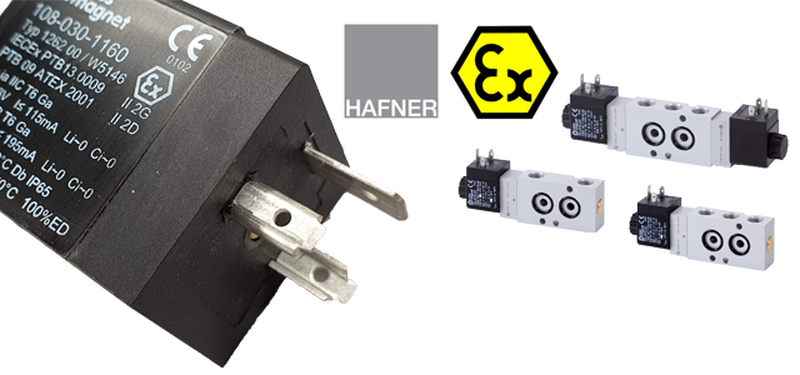

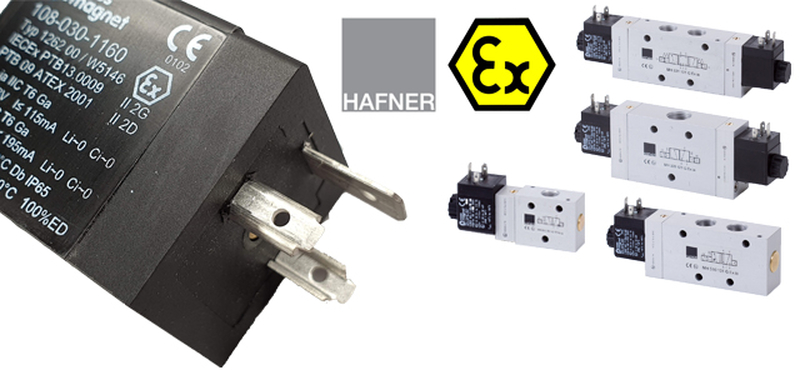

Solenoid Systems

Hafner comes with a wide variety of solenoid systems to cater to their ignition protection needs of various industries or sectors. Types available are:

● EEx na – non-sparking

● EEx ia IIC T6 – intrinsically safe

● EEx m II T4 – encapsulation

● EEx e mb IIC T6 – encapsulation with junction box

● EEx dm IIC T5 – encapsulation with junction box

● EEx d IIC T6 – flameproof with junction box

Temperature Classes

Solenoid systems are also available with support for different temperature classes. Below is a table of the different classes and their maximum permitted equipment temperature.

| TEMPERATURE CLASS | MAX. EQUIPMENT SURFACE TEMPERATURE |

|---|---|

| T1 | 450 deg C |

| T2 | 300 deg C |

| T3 | 200 deg C |

| T4 | 135 deg C |

| T5 | 100 deg C |

| T6 | 85 deg C |

Follow Us!