The Company

AKO Armaturen & Separations is a family-run company with over 35 years of experience, specializing in the manufacture of reliable, cost effective and innovative Pinch Valves technology. AKO has also earned its place as the world market leader for Air Operated Pinch Valves and best quality rubber sleeves in the market.

Operating Principle of an Air Pinch Valve

Operating Principle of a Manual Pinch Valve

Advantages of Pinch Valves

Pinch valves are simple in terms of their construction with very few parts and coupled with a full bore opening, making them ideal to handle fluids with high concentration of solids or abrasive products.

● Free passage

● Optimum tightness

● Low resistance

● No plugging

● Low air consumption

● No leakage – no bearings and seals

● Wear resistant sleeve

● Used for throttling applications

● Easy to control

● Few parts and inexpensive

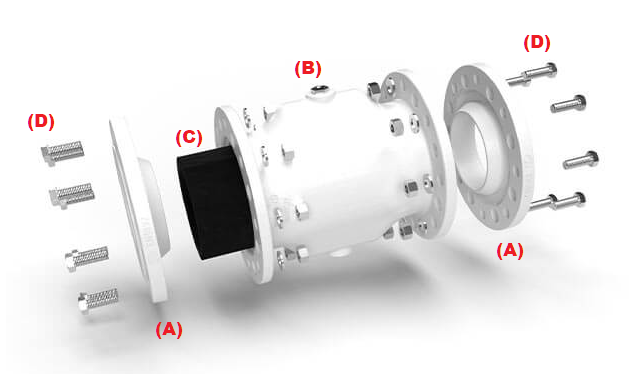

Due to the pinch valve’s simplistic design, they only consist of the following components:

(A) Flanges / End Connections

(B) Body / Housing

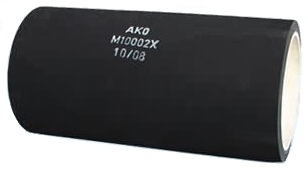

(C) Sleeve

(D) Bolts & Nuts

Pinch Valve Types

Air-operated Pinch Valves

● Flanged Connection – VF Series

● Modular Connection – VMC Series

● Internal Thread Connection – VMP Series

● Tanker Flange Connection – VT Series

Mechanical-operated Pinch Valve

Pinch Valve Sleeve Material Options

A selection of 12 different elastomer grades for the pinch valve sleeve ensures that the AKO pinch valves have a very wide and practically unrestricted field of application.

● Natural Rubber (NR) [?]

● NR food quality [?]

● NR high temperature [?]

● Neoprene® [?]

● EPDM [?]

● EPDM food quality [?]

● Viton® [?]

● Silicone [?]

● Nitrile [?]

● Nitrile food quality [?]

● Butyl [?]

● Hypalon® [?]

Note: Neoprene®, Viton® and Hypalon® are registered trademarks of E.I. Dupont Co.

Pinch Valve Applications – for Food

● Animal Feed

● Beer

● Cake Mix

● Cereal

● Dry Powders

● Effluent Water

● Extruded Pellets

● Flour

● Food Waste Recycling

● Grains

● Sauces

● Seasoning Powders and Liquids

● Oats

● Chocolate

● Seeds

● Malt Grains

● Meat Paste

● Milk

● Medical Tablets

● Nuts

● Peanuts

● Pet Food

● Sea Salt

● Salt Water

● Spices

● Starch

● Coffee

● Wine

Pinch Valve Applications – for Chemical

● Abrasive Slurry & Viscous Slurry

● Acids

● Alloy Wheel Refurb – Welding Flux

● Aluminium chips, powder, sulphate

● Barium

● Bentonite

● Biogas

● Caplets

● Carbon Ash

● Cement (dust & powder) & Concrete

● Creams & Lotions

● Detergent

● Diesel Fuel

● Dry Mortar Batching

● Dust

● Epoxy Resin

● Farming Slurry – Manure

● Fertilizer

● Fiberglass

● Glass

● Hydrated Lime

● 3D Concrete Printing

● Hydraulic Oil

● Iron Phosphate

● Latex

● Medical Tablets

● Methylene Chloride

● Nickel Pellets

● Nylon Beads

● Paint & Pigments

● Paper Pulp

● Petroleum based liquids & fuels

● Pharmaceutical Powder

● Plastic Compound

● Powder Coating

● Powders – Chemicals

● Recycled Water Systems

● Sewage & waste water slurries

● Sludge

● Soda Ash

● Sodium Hydroxide

● Talcum Powder

● Waste Material

Pinch Valve Applications – for Mineral

● Abrasive Powders

● Abrasive Dust

● Abrasive & Viscous Slurry

● Aggregates

● Aluminium chips

● Alumina – Beads & Powder

● Ceramic Beads

● Bentonite

● Carbon Ash / Carbon Black

● Clay

● Foundry Sand

● Glass

● NdPr Oxide

● Ce Carbonate

● Ce Oxide

● LaCe Carbonate

● LaCe Oxide

● SEG Oxide

● Mixed Heavy Rare Earth, SEG

● Gravel

● Grit

● Iron Phosphate

● Iron Oxide

● Lead

● Limestone

● Nickel Pellets

● Salt Water

● Sand Blasting

● Silica

● Silica Sand

● Steel Shot Blasting

● Gypsum

Pinch Valve Applications – for Ceramic Material

● Aluminium Oxide

● Barium

● Bentonite

● Calamite

● Calcined Kaolin Clay

● Calcium Carbonate

● China Clay

● Cobalt

● Dolomite

● Flint

● Soda Ash

● Zinc Oxide

● Iron Oxide

● Klin Dust

● Lead Oxide

● Lithium Carbonate

● Manganese Dioxide

● Magnesium Oxide

● Nickel Oxide

● Potash

● Feldspar

● Potassium

● Sodium Carbonate

Follow Us!